More info on LSAM: https://bit.ly/LSAM_INFO

Posted by Duane Marrett on Fri, Nov 04, 2022

Tags: Thermwood, Announcements, Trade Shows, Video, IMTS, Large Scale, Thermwood LSAM, LSAM Additive Printers

More info on LSAM: https://bit.ly/LSAM_INFO

Posted by Duane Marrett on Thu, Oct 13, 2022

Tags: Thermwood, Announcements, Trade Shows, Purdue, Large Scale, Thermwood LSAM, Ascent Aerospace, LSAM Additive Printers, Airtech, CAMX, General Atomics

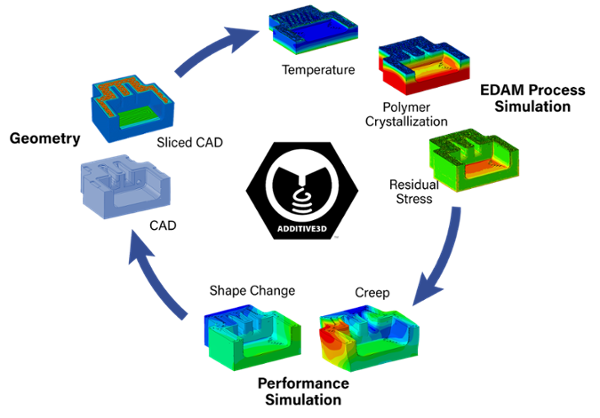

For CAMX 2022 in Anaheim, CA on October 18th-20th, Thermwood will be printing LIVE on an LSAM Additive Printer 510 – two sections of a multi-piece layup tool each day using Airtech Advanced Materials Group Dahltram™ C-250 CF carbon fiber reinforced PC material. LSAM Research Laboratory at Purdue ADDITIVE3D Software will be on display as well, with Purdue representatives on site for demonstrations. We will also have several large customer-created large scale tools on display from Airtech, Ascent Aerospace, General Atomics and more.

This promises to be an exciting demonstration of the LSAM Additive Printer Large Scale Additive System in Booth #W2.

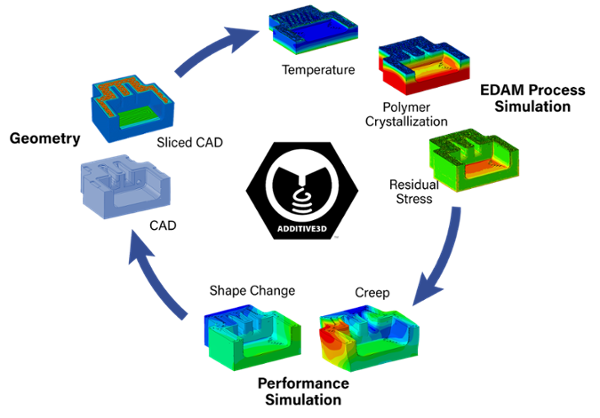

Representatives from the Thermwood Research Laboratory at Purdue University (located in Purdue University's Composites Manufacturing Simulation Center - CSMC) will also be on hand to demonstrate their ADDITVE3D simulation software.

We will be printing two sections of a multi-piece layup tool each day using Airtech Advanced Materials Group Dahltram™ C-250 CF carbon fiber reinforced PC material

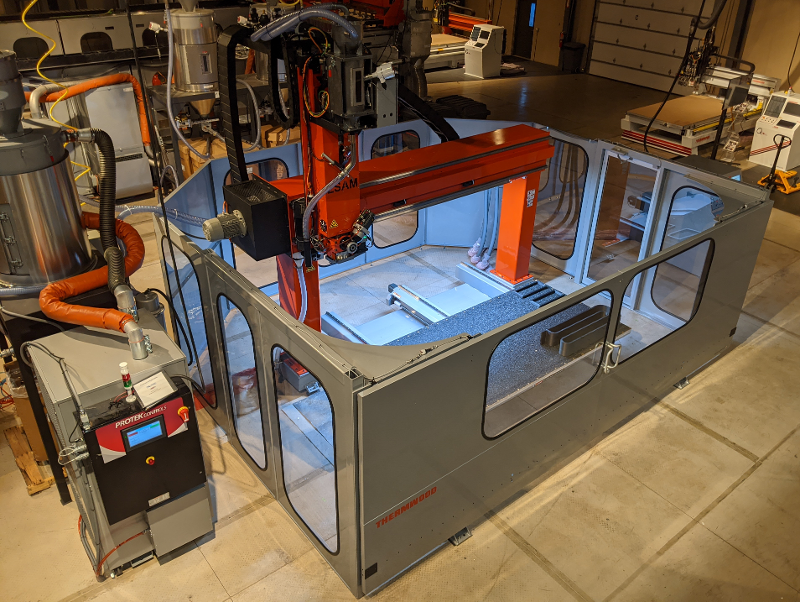

The LSAM Additive Printer systems are single gantry, moving table configurations and are available in two table sizes, 5’x5’ and 5’x10’. The 5’x10’ table is available in two configurations, 5’ wide with 10’ of front to back motion and 10’ wide with 5’ of front to back motion. Choice of configuration depends on several factors, fitting it existing factory floor space is one factor.

The specially designed, highly rigid tab and slot, structural steel gantry also incorporates a fume extraction system that pulls print fumes through specially designed activated charcoal filters to remove them and “sweeten” the air.

LSAM additive Printers use the exact same print head mechanism as all the other, including the largest LSAM Systems which means that they produce the same amazing print quality that has made LSAM the leader in large scale additive printing. They also use the same highly advanced Ultra 6 control with all its exclusive, patented print features and capability.

The systems come standard with a single hopper polymer dryer for applications that don’t change print material very often. For installations that print a wider variety of materials, a dual hopper dryer is available as an option.

An enclosure that surrounds the machine is also available. The machine with the full enclosure can also be built to meet European CE standards.

Posted by Duane Marrett on Wed, Jun 15, 2022

Tags: Thermwood, tooling, LSAM, Thermwood LSAM, LSAM 1020, Spirit Aerosystems, Additive tooling

It was determined that carbon fiber filled polycarbonate would provide sufficient strength to withstand the significant forces used in the stretch form process, however unlike traditional lubrication methods, Techmer PM blended a new polycarbonate formulation that contained an internal lubricant in addition to the carbon fiber, eliminating the need for any additional lubrication.

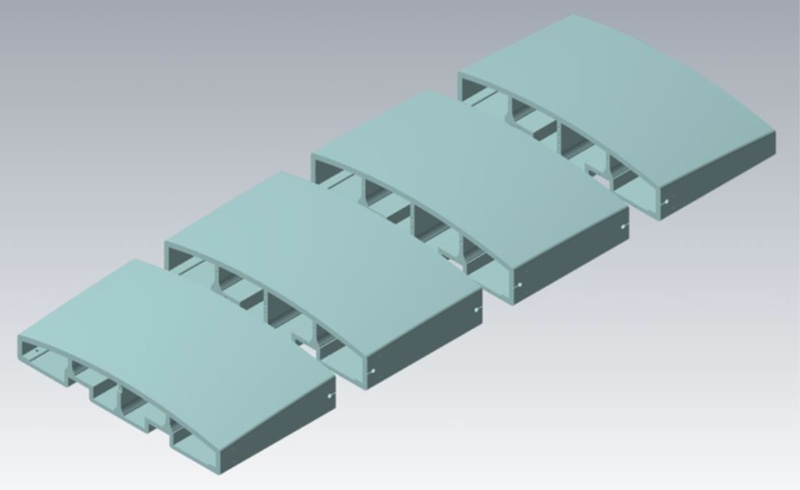

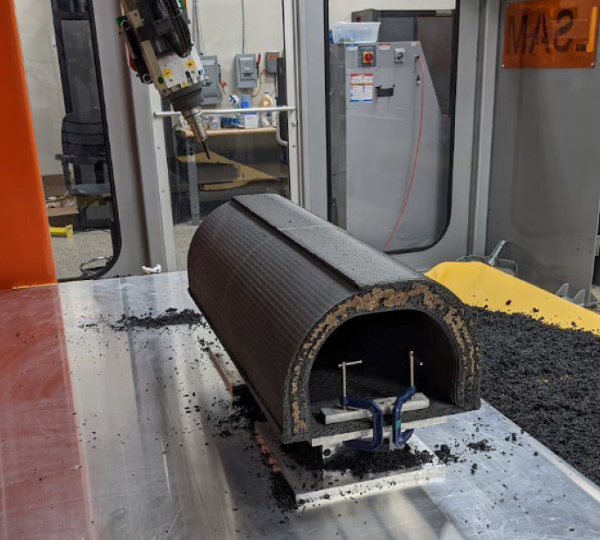

The tool was printed on Thermwood’s LSAM 1020 dual gantry print and trim system. While this machine is equipped with Vertical Layer Printing and could have printed the tool in one piece, because it requires that you to wait for each printed layer to cool enough before adding the next layer, it would have required 58 hours of continuous print time to produce a one-piece tool. Instead they decided to print the part in four sections, two at a time for a total print time of 29 hour and 20 minutes, cutting the print time in half. Printing required 3,613 pounds of material.

The Four Parts Printed

The four parts then needed to be machined and assembled.

Layout of the Assembly

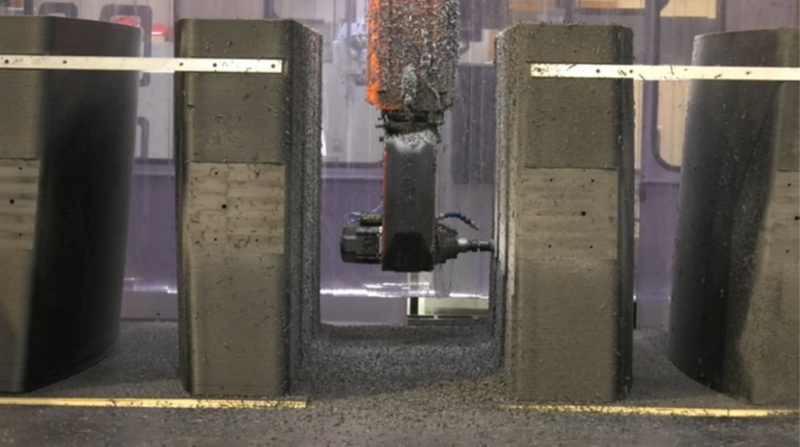

All surfaces of the parts except for the front working surface were then machined in place.

Initial machining. The holes in the center of each side are for center-of-gravity brackets used for part handling during assembly.

The mating faces were then machined flat except for slightly raised bosses which insured proper gapping for the adhesive. Adhesive is only one part of a multi part approach used to permanently and securely attach the parts to each other. These are all highly accurate, precision surfaces.

Flat Face has raised bosses to provide proper adhesive gap

Draw bolt holes and slots were machined into the back of the tool which allow the parts to be bolted together in addition to the adhesive.

Machined area for draw bolts

In addition to adhesive and draw bolts, alignment holes and countersink holes were machined into the center sections of the tool.

The 6-inch long alignment pins for these holes are machined with adhesive channels providing not only alignment between parts but also another level of permanent attachment.

Heavy duty alignment pins offer another attachment layer

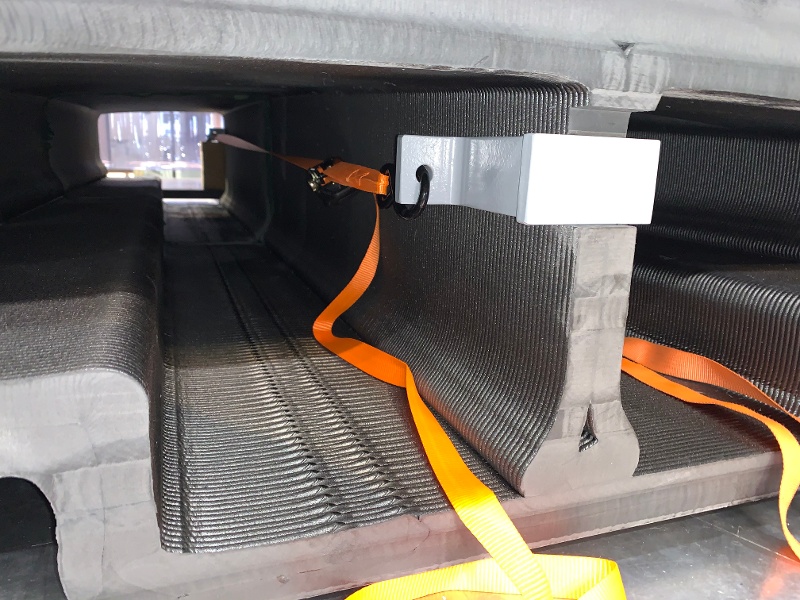

The next level of attachment uses brackets positioned inside the structure near the front surface, which are attached to each other using tensioned aircraft steel cables, securely holding the front surface of the four parts together.

Brackets with temporary straps which were replaced by tensioned steel cables

The parts were then final assembled using another unique approach. Each part is relatively heavy and because of relatively short open time for the adhesive, there is a limited amount of time available during assembly to apply the adhesive and mate the parts securely together. The parts need to be pushed together while aligned, literally within a few thousandths of an inch and need to be mated absolutely even and square. This turned out to be fairly easy using the Vertical Layer Print table mechanism installed on the LSAM machine.

The parts were carefully hand fitted together. Then, one part was attached to the machine table and the other to the mechanism that moves the vertical table. The vertical table drive then moved the parts apart about 20 inches, adhesive was applied and the vertical table mechanism pushed the parts back together again, square and perfectly aligned.

Adhesive being applied to separated pieces

Draw bolts and cables were permanently attached and after the adhesive fully cured, the completed tool front surface was machined to final dimensions using the LSAM trim head. When Spirit AeroSystems measured the final working surface it was within +/- 0.005”, well within their requirements. Total of all machining including the final working surface was 118 hours and 58 minutes.

Front surface measured to within +/- 0.005"

Spirit AeroSystems then stretched 10 skin panels of 0.050” thick 2024 T3 aluminum to 5% elongation. The press controller showed that each jaw gripping the aluminum sheet had ~100 tons of load on it, so ~200 tons in total. Everything was kept under the same conditions as if running a production part and although the printed tool was considerably lighter in weight than their traditional tools, it appeared to perform in a similar manner.

Skin panel being stretched

This is a first step. There are additional tests to be performed and more data to be collected, but it does appear that large 3D printed composite stretch form tools can be produced using currently available material and current equipment, saving considerable time and money and opening yet another application for this exciting new technology.

Spirit AeroSystems is one of the world's largest manufacturers of aerostructures for commercial airplanes, defense platforms, and business/regional jets. Also, Spirit serves the aftermarket for commercial and business regional jets.

Thermwood is a US based, multinational, diversified machinery manufacturer that has become the technology lead in large scale additive manufacturing of thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) systems that both 3D print and trim on the same machine.

Posted by Duane Marrett on Tue, May 17, 2022

Tags: Thermwood, Announcements, Thermwood LSAM, LSAM Additive Printers, RAPID + TCT

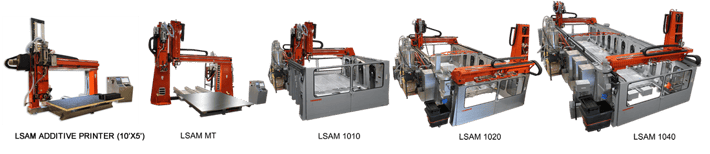

Thermwood Corporation, manufacturer of some of the largest composite thermoplastic additive manufacturing systems operating in industry today, has announced the availability of a new line of lower cost “print only” LSAM systems, called LSAM Additive Printers.

Thermwood’s current LSAM line of large scale, dual gantry, “print and trim”, near-net-shape additive manufacturing systems use an advanced print technology that produces high quality, fully fused products from a wide variety of reinforced composite thermoplastic polymers, including materials that process at high temperature like PSU, PESU, and PEI.

These systems are being used primarily to produce molds and tooling, most for aerospace and industrial production applications.

To accommodate the request for a lower cost system, Thermwood refined and updated the gantry structure of its highly successful 5 axis CNC routers. This machine was re-engineered to use the incredibly strong “slot and tab” structural steel approach used on flagship LSAM machines. The same table, base structure and servo drives used on their five axis CNC routers could be used pretty much as is. With these changes the “LSAM Additive Printer” was born.

Although smaller than the flagship systems, it is capable of producing large parts at temperatures up to 450° C, with overall size limited primarily by the table size and working envelope.

The new LSAM Additive Printers are all fixed gantry, moving table designs with table sizes of 5’x5’ and 5’x10’ and are capable of printing parts up to 4’ high. The 5’x10’ machines are available in two styles, 5’ wide with 10’ of front to back motion or 10’ wide with 5’ of front to back motion. Maximum table print weight is 1,000 pounds, however, the 10’ wide 5’ deep machine is available with a dual servo drive which doubles the weight carrying capability. It is planned to equip the 5’ wide 10’ deep version with a Vertical Layer Printing option which will allow it to vertically print parts up to ten feet tall.

For trimming printed parts, Thermwood recommends our new LSAM Additive Trimmer, which is available in the same table sizes as these new LSAM Additive Printers. It is available with up to 5’ of vertical travel, allowing it to trim completely around and over the top of the largest part the LSAM Additive Printer can print. As an added benefit, with both an LSAM Additive Printer and an LSAM Additive Trimmer, you can print and trim at the same time.

Although having a new LSAM Additive Printer plus an LSAM Additive Trimmer requires purchasing two machines, the combined cost of both is just over a third of the cost of an LSAM 1020 (which is currently the smallest flagship LSAM system that can both print and trim at the same time). The LSAM 1020 does have a much larger table, faster print head and the ability to do vertical layer printing up to 20 feet long, however, if you don’t need those capabilities, the new LSAM Additive Printers may be an answer. If you already have trim capability, the cost can be even lower.

The same powerful, feature rich LSAM control used on the large flagship LSAM systems, along with all its unique patented additive print features is standard on the new LSAM Additive Printers. A system for drying and conveying pelletized polymer material is also included as is a liquid chilling system to maintain temperature control on vital systems. This is especially important when processing high temperature materials.

An optional enclosure that surrounds the machine is available. The machine with this full enclosure can also be built to meet European CE standards.

The machine comes standard with a single hopper material dryer, however, an optional dual hopper dryer is also available for applications that change materials often.

Thermwood’s new Thermal Sensor Layer Automation System is also available on the LSAM Additive Printers. This is an exciting new system that automates the print process to easily and automatically obtain the highest quality layer to layer fusion.

With this system, a servo controlled thermal sensor, which travels with and rotates around the print nozzle, measures the temperature of the bead an instant before a new bead is added. This data is sent to the control which automatically adjusts print speed to print at the precise temperature that results in the best bead fusion for that particular polymer. Thermwood’s

LSAM print technology already produces the best quality, strongest large scale additive parts and this system not only makes it better but also easier.

The same Thermwood LSAM Print 3D slicing software used on all the other LSAM systems is used to program LSAM Additive Printers. Several levels of software training are available.

This new LSAM Additive Printer is intended to introduce LSAM additive technology to a whole new level of application and customer. It targets companies that want to print top quality, large composite thermoplastic parts, but don’t really need, nor can they cost-justify, the really large LSAM systems. These new systems also target companies who already have sufficient trimming capability and may only need a quality print function. Applications include industrial fixtures, molds (including high temperature molds), tooling, foundry patterns, and hundreds, if not thousands of similar applications.

With the addition of the LSAM Additive Printers, Thermwood now offers the largest selection of large scale additive manufacturing systems for thermoplastic composite materials in the industry with models available for just about every application and budget.

Posted by Duane Marrett on Tue, Apr 12, 2022

Tags: Thermwood, Announcements, Purdue, Thermwood LSAM, Thermwood LSAM Research Laboratory

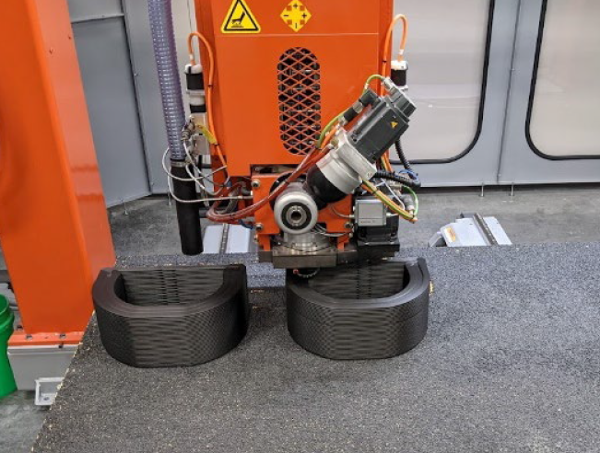

Purdue CMSC, in collaboration with Purdue Silicon Detector Laboratory (PSDL), is designing, prototyping, testing, and fabricating composite support structures for CERN’s Large Hadron Collider (LHC) CMS and ATLAS experiments. This is part of the particle collider’s High Luminosity upgrade, with installation of final components in 2026-27. The Thermwood LSAM 105 Additive Printer and five-axis LSAM Trim router at the Purdue LSAM Research Laboratory have enabled rapid large-scale printing and machining of trimming fixtures for the high precision composite tube structures. The 1m long, 208mm radius trimming fixture was printed on the LSAM with Acrylonitrile Butadiene Styrene (ABS) reinforced with 20% by weight of carbon fiber.

This 914mm long prototype of the CMS upgrade inner tracker support tube will allow project partners at national labs, universities around the world, and CERN to begin installation tests of their structural and detection components. Individual components installed into this support tube are expected to be positioned within +/- 0.5mm or less, so accurate machining of interface features is critical. This kind of precision at large scale is made possible, economical, and convenient with the aid of systems like LSAM.

Printing Details

Machining Details

The faces that would become the trimming fixture base were machined to the flatness required for fixturing later. The printed, bonded fixture was then mounted on pedestals in the LSAM Additive Trimmer and the surface was machined to fit the nominal inner surface shape of the composites half-cylinders to be trimmed. Edge finding and reference features were machined into the trimming fixture to allow proper centering of the cured composite part.

Final Result

The final tube, 3.2m long, has to support 140kg of mass while only allowing sub millimeter deflections to occur. Purdue CMSC and PSDL will also be designing, fabricating, or testing other composite support structures for the CERN LHC upgrade as small as 0.5mm sheet goods and as large as 2.4m x 5m sandwich panel tubes. It is planned for the LSAM system to be utilized to create tooling and some final components for these other structures.

The Composites Manufacturing and Simulation Center (CMSC) of the College of Engineering and the Purdue Polytechnic are located in over 30,000 square feet of the Indiana Manufacturing Institute building. CMSC consists of faculty experts in composites manufacturing, a professional staff of doctoral degree engineers, a support staff and research students in doctoral, masters and bachelor’s degree programs of the Schools Aeronautics and Astronautics, Chemical Engineering and Materials Engineering, as well as, the Department of Aviation Technology in the Polytechnic.

A comprehensive set of laboratories is available at the IMI for the study of composites manufacturing processes, characterization of composite materials, and the validation of simulation software essential to development and verification of the digital twin concepts in composite manufacture and performance. Focus specialties include extrusion deposition additive manufacturing, composites autoclave processing of continuous fiber systems, compression and injection molding of discontinuous fiber composites, prepreg impregnation, infusion molding, sheet forming, complex mold-forming and hybrid continuous/discontinuous fiber systems. Workflow simulations are being developed to provide for end-to-end digital twins of these manufacturing processes. Accordingly, manufacturing informed performance predictions are a direct outcome of these workflow analyses.

About Thermwood Corporation

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

Posted by Duane Marrett on Tue, Jan 18, 2022

Tags: Thermwood, Announcements, Thermwood LSAM, Patented, VLP, ALP, HLP, Compression Wheel

Virtually all, if not all, large format, FDM additive systems, sold to industry in the last several years have been Thermwood LSAMs.

Watch the video below to learn 21 reasons why:

Posted by Duane Marrett on Tue, Jan 04, 2022

Tags: Thermwood, Announcements, Local Motors, Thermwood LSAM, Patented, Boeing, Navair, Al Davis Torch, General Atomics

Thermwood routinely applies for patent protection on additive manufacturing technology it develops for its LSAM large format additive systems. During COVID, we received electronic copies of patents that were granted, however, the official hard copies were withheld.

A couple of days before Christmas 2021, we received a package containing the official hard copy of 32 additive manufacturing patents. This was certainly a one-day record for Thermwood and a welcome sight!

In addition to these latest patents, Thermwood already has a large portfolio of earlier issued patents covering the unique, large format (5x10 foot table and larger) 3D print technology it has developed. This LSAM technology is currently the most widely used large scale additive print technology operating in industry today. It’s used in a wide variety of industries including aerospace, transportation, heavy equipment, foundry and large decorative structures. It is being used to produce a diversity of products including aerospace patterns, molds and tooling, heavy equipment foundry patterns, bus chassis, large valve body foundry patterns and trim tooling. It was even used to print the tallest 3D printed structure in the world, the 92 foot tall Al Davis Memorial Torch at Allegiant stadium in Las Vegas.

Thermwood offers this unique patented technology on a wide variety of equipment, the largest, most diverse product offering of its kind available today. It includes a broad selection of machines, including single and dual gantry, fixed and moving table configurations, with both print-only and print-and-trim systems, from 5 by 10 foot to 20 by 60 foot print envelopes. We are working on even larger machines but that’s for another day.

The primary focus of the patented LSAM technology is to reliably and repeatedly produce the highest quality, best fused, most homogeneous printed structures possible from a variety of reinforced thermoplastic polymer composites including those intended to operate at elevated temperatures. Although it is nice to have been granted these patents, it is even nicer to finally have the official hard copies in hand.

Posted by Duane Marrett on Tue, Nov 30, 2021

Tags: Thermwood, Announcements, Thermwood LSAM, VLP, ALP

Thermwood has added a third print orientation to its LSAM Large Scale Additive Manufacturing systems.

LSAM systems currently can print both horizontal and vertical layers if equipped with the Vertical Layer Print (VLP) option, available on most Thermwood LSAM machines. This new addition adds Angle Layer Printing (ALP) to the VLP option. Angle Layer Printing is the ability to print at a 45 degree angle.

LSAM Angle Layer Printing (ALP) shown

LSAM Regular Vertical Layer Printing (VLP) shown

LSAM Horizontal Layer Printing (HLP) shown

Each print orientation has advantages and limitations for a particular part design. Offering all three on the same machine, for the first time, means maximum print flexibility. All print orientations use the complete LSAM print head including exclusive LSAM print features such as the patented compression wheel and Thermal Sensor Layer Automation.

This helps maintain an even layer temperature throughout the print. LSAM automatically adjusts the individual layer temperature to provide for superior layer fusion (as seen below).

LSAM machines are currently operating in regular daily industrial production with many existing systems already equipped with Vertical Layer Print capability. The Vertical Layer Print (VLP) option has been replaced with a VLP/ALP option on new machines which offers both vertical and angle layer print capability, in addition to the standard horizontal layer print.

Angle Layer Print (ALP) can be easily and inexpensively added to machines operating in the field that already have the VLP option.

If a machine was purchased without VLP, the entire new VLP/ALP Print option, can be added to most machines already in operation. It can be done in the field, but is a bit more involved.

Thermwood’s LSAM large scale additive systems are the most widely used large scale composite thermoplastic additive equipment in industrial production today. Virtually all, if not all, large scale additive systems installed in the last several years have been Thermwood LSAMs. Processing a variety of reinforced composite polymers from room temperature ABS and PC to high temperature material such as PSU, PESU and PEI, they are used to produce molds and tools for the aerospace industry, patterns for the foundry industry and for a variety of other unique applications.

LSAM systems are available in sizes from 5x10 foot to 15x60 foot in a variety of configurations including print only and full print and trim, making it the broadest product offering in the large scale additive arena. Print heads are available that can print thermoplastic composite material at rates from 200 pounds per hour to over 500 pounds per hour.

They have a variety of exclusive features including a temperature controlled compression wheel and automatic thermal layer speed control, both of which help assure the best possible fusion between printed layers.

With the addition of Angle Layer Print, these systems have become even more capable and more flexible.

Finished LSAM Angle Layer Print (rear view)

Finished LSAM Angle Layer Print (front view)

Posted by Duane Marrett on Fri, Oct 01, 2021

Tags: Thermwood, Announcements, Trade Shows, Large Scale, Thermwood LSAM, SABIC, LSAM Additive Printers, Airtech, High Temperature, Techmer PM, CAMX

Thermwood will be printing high temp autoclave aerospace tooling on an LSAM Additive Printer 510 LIVE at CAMX 2021 in Dallas, TX, October 19th-21st in Booth #M44B. LSAM Research Laboratory at Purdue ADDITIVE3D simulation software will be on display as well in adjacent Booth #M44, with Purdue representatives on site for demonstrations. We will be printing a different material each day, donated by AIRTECH, SABIC AND TECHMER PM. This promises to be an exciting demonstration of the LSAM Additive Printer Large Scale Additive System!

Click the link below to Be Our Guest and register for a Free CAMX Exhibit pass and 15% off the Conference Registration Fee.

Free Exhibit Hall Pass Code: FREEEX021

15% off Full Conference Registration Code: FREEFULL21

Make plans now to visit the Kay Bailey Hutchinson Convention Center and stop by Thermwood Booth #M44B to witness this live and in-person!

Representatives from the recently announced Thermwood Research Laboratory at Purdue University (located in Purdue University's Composites Manufacturing Simulation Center - CSMC) will also be on hand to demonstrate their ADDITVE3D simulation software.

On Tuesday, October 19th, we will be printing AIRTECH PEI DALTRAM I-350CF

On Wednesday, October 20th we will be printing SABIC LNP™ THERMOCOMP™ AM EC004XXAR1 ULTEM compound.

On Thursday, October 21st, we will be printing TECHMERPM PESU 1810 3DP.

Posted by Duane Marrett on Thu, Sep 02, 2021

Tags: Thermwood, Announcements, Trade Shows, Large Scale, Thermwood LSAM, SABIC, LSAM Additive Printers, RAPID + TCT, Airtech, High Temperature, Techmer PM

Thermwood will be printing high temp autoclave aerospace tooling on an LSAM Additive Printer 510 LIVE at RAPID + TCT 2021 in Chicago, IL September 13th-15th. LSAM Research Laboratory at Purdue ADDITIVE3D Software will be on display as well, with Purdue representatives on site for demonstrations. We will be printing a different material each day, donated by SABIC, TECHMER PM and AIRTECH. This promises to be an exciting demonstration of the LSAM Additive Printer Large Scale Additive System.

Click the link below to Be Our Guest and register for a Free Rapid + TCT Expo pass and $100 off the Conference Registration Fee.

Use Promo Code: 10016220

Make plans now to visit the McCormick Center and stop by Thermwood booth #E7628 to witness this live and in-person!

Representatives from the recently announced Thermwood Research Laboratory at Purdue University (located in Purdue University's Composites Manufacturing Simulation Center - CSMC) will also be on hand to demonstrate their ADDITVE3D simulation software.

On Monday, September 13th we will be printing SABIC LNP™ THERMOCOMP™ AM EC004XXAR1 ULTEM compound.

On Tuesday, September 14th, we will be printing TECHMERPM PESU 1810 3DP.

On Wednesday, September 15th, we will be printing AIRTECH PEI DALTRAM I-350CF

© Thermwood Corporation. All Rights Reserved