Smart-routers support pause technology. The operator is no longer forced to remain at the machine to stop it in an emergency. A pause button clipped to his belt can stop the machine, so the operator is free to perform other tasks away from the control. A progress bar, visible from a distance, shows the operator how long before he needs to service the machine. It’s like getting an extra worker for free.

Pause button allows machine operator to safely do other jobs

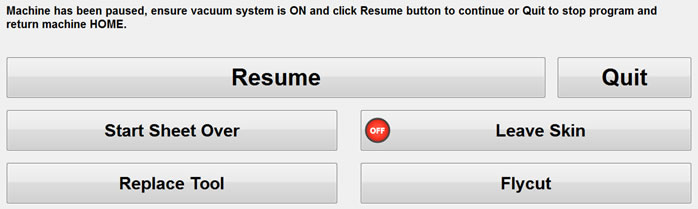

With standard routers, the operator must remain close to the control so he can stop the machine if something goes wrong. The only job he can really do is watch the machine. With a smart-router, a pause button clips to his belt. Pressing it anywhere in the production cell stops the machine. It works like an emergency stop, but is not a “wrench in the gearbox” emergency stop. It immediately stops the machine, but offers options:

With standard routers, the operator must remain close to the control so he can stop the machine if something goes wrong. The only job he can really do is watch the machine. With a smart-router, a pause button clips to his belt. Pressing it anywhere in the production cell stops the machine. It works like an emergency stop, but is not a “wrench in the gearbox” emergency stop. It immediately stops the machine, but offers options:

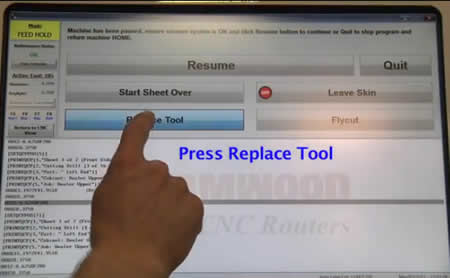

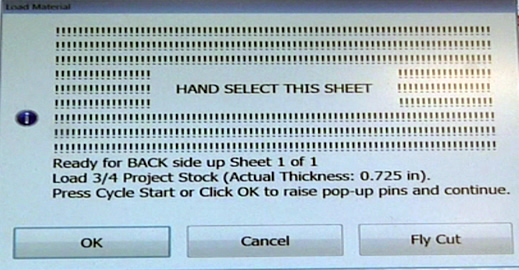

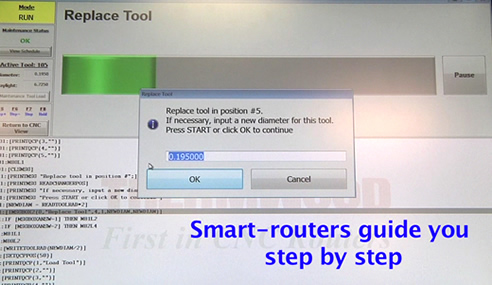

If you break a tool, the smart-router drops off the tool holder and tells you to replace the tool. It then picks up the new tool, automatically measures it, adjusts the program for the new tool length and diameter, recuts the path of the broken tool and continues with the job. You can also abandon and recut the sheet you are working on. Perhaps the sheet is warped or you found an internal defect when you started cutting. The machine gives you step by step instructions to replace and recut the sheet, right in the middle of the job.

If you break a tool, the smart-router drops off the tool holder and tells you to replace the tool. It then picks up the new tool, automatically measures it, adjusts the program for the new tool length and diameter, recuts the path of the broken tool and continues with the job. You can also abandon and recut the sheet you are working on. Perhaps the sheet is warped or you found an internal defect when you started cutting. The machine gives you step by step instructions to replace and recut the sheet, right in the middle of the job.

Perhaps some parts are moving because you didn’t fly-cut the spoilboard soon enough. You can instruct the machine to go ahead and finish this sheet, but leave a skin on all remaining parts so they won’t move and be scrapped. You can easily trim the skin afterwards and save the parts. By the way, smart-routers can fly cut a spoilboard in the middle of a job, then adjust the program for the new spoilboard thickness and finish the job. If these types of problems are encountered on an ordinary router, addressing them is much more involved.

If you think about it, just the labor saving of being able to use the machine operator to do other tasks in the production cell is enough to pay for the upgrade to a smart-router. The savings in scrap, labor and programing when you encounter a problem makes it that much better.

By the way, not fly cutting the spoilboard soon enough to keep parts from moving is probably the single most common reason for scrapping parts in nested based machining. Smart-routers try to help by keeping track of where you have cut into the spoilboard as you machine parts. Before instructing you to load another sheet, it looks at the parts on the next sheet and at the cuts already in the spoilboard and makes sure every part has sufficient hold down area so it won’t move. If any part falls below a minimum, it gives the operator a choice, either fly cut the top before continuing or it will leave a skin on the problem part so it remains connected to other parts around it and doesn’t move. Over time this saves a ton of scrap, a lot of time and a lot of money.

|

|

|

Please click the "Request a Consultation" link above or give us a call at 1-800-533-6901 and we will sit down and show you how all this happens, in detail.

|

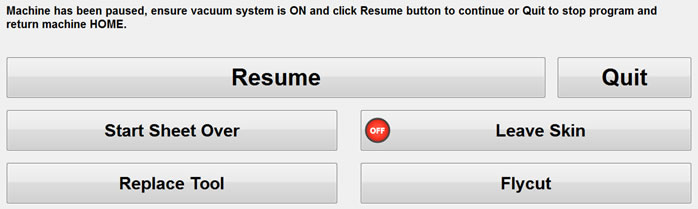

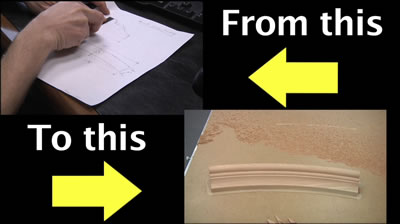

Smart-routers allow you to nest around defects to use damaged or flawed material. This feature can save you a lot of material, which in turn can save you a lot of time and money.

Smart-routers allow you to nest around defects to use damaged or flawed material. This feature can save you a lot of material, which in turn can save you a lot of time and money.

Replacing bad or scrap parts is really easy with a

Replacing bad or scrap parts is really easy with a

Smart-routers give you more

Smart-routers give you more Smart-routers alert you when running critical or prominent parts. Certain parts are prominent on the final product, door and drawer fronts for example.

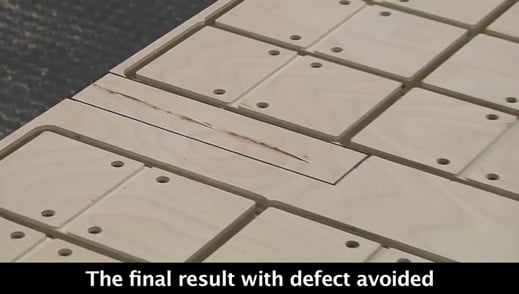

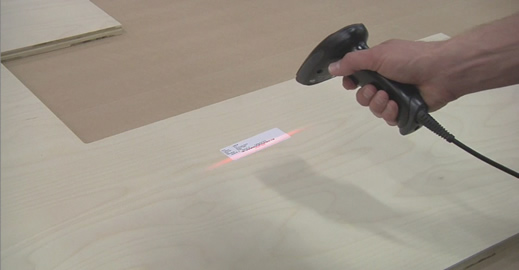

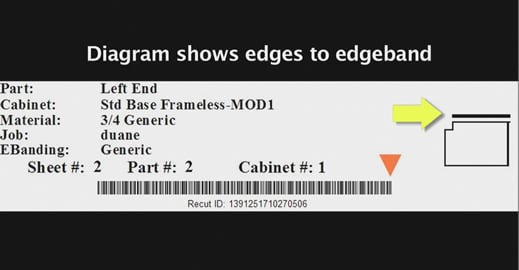

Smart-routers alert you when running critical or prominent parts. Certain parts are prominent on the final product, door and drawer fronts for example.  Smart-routers use smart labels to make parts easy to sort and edgeband.

Smart-routers use smart labels to make parts easy to sort and edgeband. AWFS 2013 (July 24th-27th) promises to be an exciting time to visit Las Vegas. This year, Thermwood is proud to demonstrate our affordable

AWFS 2013 (July 24th-27th) promises to be an exciting time to visit Las Vegas. This year, Thermwood is proud to demonstrate our affordable  Sign up below to schedule a time during the show to meet with one of our CNC Experts (Booth #8400). They will evaluate your production needs to determine how you can best reduce costs and increase efficiency. Plus, receive a FREE 2 GB Flash Drive during your meeting!

Sign up below to schedule a time during the show to meet with one of our CNC Experts (Booth #8400). They will evaluate your production needs to determine how you can best reduce costs and increase efficiency. Plus, receive a FREE 2 GB Flash Drive during your meeting!

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.